Dynamic surface tension and surfactants

|

Measuring the dynamic surface tension offers new possibilities for using tensiometers in various industries. Due to time-related measurements this measuring principle is able to differentiate even high concentrations of surface-active substances (surfactants) and at the same time pick up characteristic curves of their wetting behavior.

|

Advantages of dynamic surface tension measurements

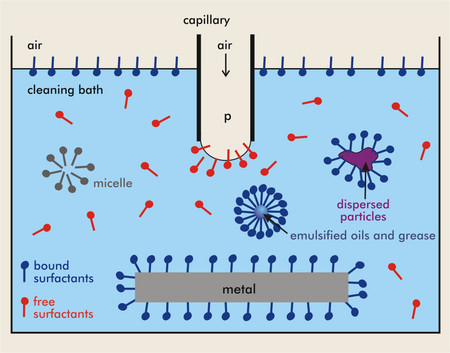

If an interfacial surface (i.e. parts surface) gets in contact with a liquid that contains surfactants, it is free of surfactants in the beginning. Due to a concentration gradient between the liquid and the new interfacial surface, the surfactant molecules move towards the interfacial surface and thus, reduce the interfacial surface tension. This process requires a certain time which depends on the concentration and the mobility of the surfactants in the liquid.

Above a certain surfactant concentration which is called critical micelle formation concentration CMC the surfactants that are ‘not needed’ form micelles. In cleaning baths those micelles are a depot from which used surfactants are recruited. Therefore, the surfactant concentration in cleaning baths is considerably higher than the CMC and cannot be differentiated with normal static tensiometers.

Measurement methods

On a geometric constant surface an absorption equilibrium is established relatively quickly at a low surfactant concentration – the interfacial surface tension reaches an equilibrium value that can be determined with static (Wilhelmy plate) or quasi-static (du Noüy ring) measuring methods. Surfactants that have formed micelles have no influence on the measurement which means that the total surfactant concentration in cleaning baths cannot be determined with a static or quasi static tensiometer.

On a continuously expanding surface, new surface elements are constantly added which means that the actual equilibrium is disturbed and can’t be achieved. Dynamic measuring systems show higher surface tension measuring values than static methods.

Measuring devices

Bubble pressure tensiometers create a bubble and thus, new expanding surface. Micelles that are close to the new interfacial surface provide surfactants even before surfactant molecules that are farther away join the bubble and therefore, have influence on the dynamic surface tension of the bubble. There is a clear correlation between the surfactant concentration and the dynamic surface tension even above the CMC.

SITA offers measuring devices that determine the surfactant concentration in cleaning baths – with a ‘measuring body’ that doesn’t have to be cleaned, but instead is newly developed with each bubble.